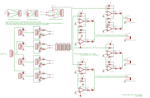

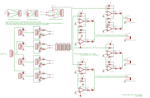

NOTE: the headphone amp pictured in the schematic is optional and not included in the BOM below...

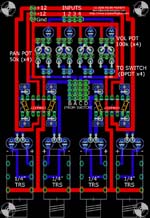

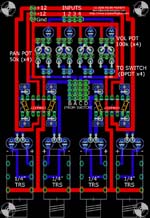

. (eagle schematic here)

. (eagle schematic here)

A bill of materials (BOM) for the audio mixer:

NOTE: the headphone amp pictured in the schematic is optional and not

included in the BOM below...

. (eagle schematic here)

. (eagle schematic here)

| picture | qty | item | placement | buy it |

| 5 | SIL 4 pin headers (optional, use polarized headers) | HD0,31,32,33,34 | futurlec, smashtv, mouser, digikey |

| 9 | SIL 3 pin headers | HD1,2,3,4,11,12,13,14 | |

| 4 | SIL 2 pin headers | HD21,22,23,24 | |

| 5 | SIL 4 pin connectors | CN0,31,32,33,34 | |

| 9 | SIL 3 pin connectors | CN1,2,3,4,11,12,13,14 | |

| 4 | SIL 2 pin connectors | CN21,22,23,24 | |

| 4 | 10uF non-polar (aka. bi-polar) electrolytic capacitor (at least 35V, 50V should be fine) | C1,2,3,4 | mouser |

| 16 | 20k %5 resistor | R201,202,203,204,205,206,207,208, 211,212,213,214,215,216,217,218 | mouser |

| 2 | OPA4227 | IC1,2 | texas instruments, digikey |

| 4 | 100pF ceramic disc capacitor | C13,17,19,20 | mouser |

| 4 | 15pF ceramic disc capacitor | C14,15,16,18 | mouser |

| 6 | 59k %5 resistor | R11,12,14,15,18,19,20,21 | mouser |

| 8 | 100ohm %5 resistor | R1,2,3,4,5,6,7,8 | mouser |

| 8 | 1uF non-polar (aka. bi-polar) electrolytic capacitor (at least 35V, 50V should be fine) | R5,6,7,8,9,10,11,12 | mouser |

| 4 | 100k linear potentiometer | VR1,2,3,4 | futurlec, mouser |

| 4 | 50k linear potentiometer with center detent (for pan pot) | VR11,12,13,14 | futurlec, mouser |

| 4 | DPDT slide switch (ON-ON or ON-OFF-ON if you want the ability to disable an input... switch should have 6 pins on the bottom, 2 inputs that are routed to 4 outputs) | SW1,2,3,4 | futurlec,mouser |

| 2 | 14 pin DIP socket for the OPA4227 (optional) | IC1,2 | mouser |

| -- | wire for connectors/headers/pots/switches/inputs try to match the header pins, stranded wire will be stronger for flexing... be neat and tidy and use ribbon cable | ----- | mouser, futurlec, digikey |

<- vector <- vector <-

futurlec <-

futurlec | 1 | Vector Electronics 8015-1

circboard

(4"x4") (or proto board, perfboard, veroboard) If choosing some other brand: - the PCB layout above requires at least 27 x 36 holes - the kind with a copper pad for each hole is ideal - through hole plating with pads on both sides even better optional: You could etch your own PCB instead, protoboards can be easier for some people. also, you could use futurlec to make the board for you, as low as $25 | PCB | newark (vectorboard 8015-1), futurlec ($1.50 CHEAP! one-side copper pads, 120x80mm, requires cutting down to allow audio jacks to hang off for panel mounting.) mouser(4"x5" twin industries) |